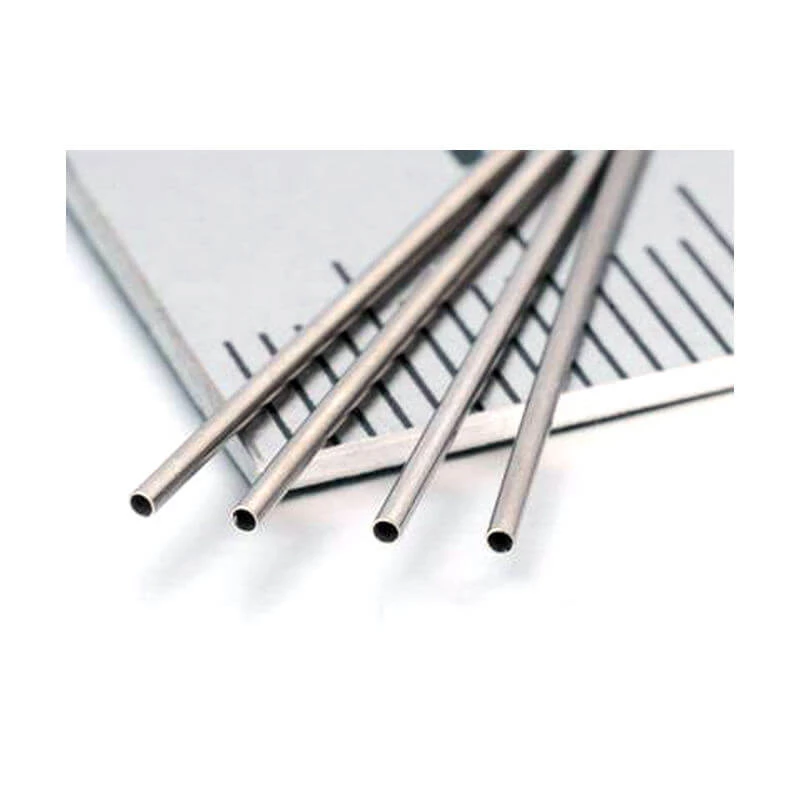

Titanium tubes have the feature of light weight, high strength and superior mechanical properties. Titanium tubes are widely used in heat-exchange equipment, such as tube type heat-exchanger,coiled type heat-exchanger,coil heat-exchanger, condensator,evaporator and transmission pipeline. Many nuclear power industry ues titanium tubes as the unit standard tubes.

| Product Name | Cp1 Cp2 seamless titanium tube titanium pipe |

| Material | Pure titanium and Titanium alloy |

| Titanium Grade | Grade 1—Unalloyed titanium |

| Grade 2—Unalloyed titanium | |

| Grade 3—Unalloyed titanium | |

| Grade 7—Unalloyed titanium plus 0.12 to 0.25 %palladium | |

| Grade 9—Titanium alloy (3 % aluminum, 2.5 % vanadium) | |

| Grade 12—Titanium alloy (0.3 % molybdenum, 0.8 % nickel), | |

| Standard | ASTM B338/ASME SB338, ASTM B337/ASME SB337, ASTM B861/ASME SB861, ASTM B862/ASME SB862,AMS4911,AMS4928 |

| Shape | Round Square Rectangle |

| Type | Seamless/Welded |

| Processing | Seamless titanium tube: Titanium sponge—Compacting electrodes—melting—Forge—Bar billets—Extruding—Rolled—Straightening—Seamless tube |

| Welded titanium tube: Titanium sponge—Compacting electrodes—melting—Forge—Plate billets—Hot rolled—Cold rolled—Titanium scrap—Welded—Welded tube | |

| Surface | Polishing, picking, acid washed, black oxide |

| Application | 1) General service industries (petroleum, food, chemical, paper, fertilizer, fabric, aviation and nuclear |

| 2) Fluid, gas and oil transport | |

| 3) Pressure and heat transmission | |

| 4) Construction and ornament | |

| 5) Boiler heat exchangers | |

| 6) Motorbycle and bike | |

| Material Milling Certificate | According to. EN 10204.3.1 |

| Including Chemical composition and Mechanical property |

| Standard | ASTM B337, ASTM B338, ASTM B861, ASTM B862 |

| Specification | OD5.0-114.0mm x WT0.5-7.0mm x 1000-12000mm |

| OD55mm-914mm x WT1.0-10.0mm x 1000-6000mm | |

| Or according to customer’s requirement. | |

| Payment | T/T, L/C ,Paypal, as your inquiry |

| Technique | Rolled |

| Condition | Annealed(M) |

| Application | a) General service industries (petroleum, food, chemical, paper, fertilizer, fabric, aviation and nuclear) |

| b) Fluid, gas and oil transport | |

| c) Pressure and heat transmission | |

| d) Construction and ornament | |

| e) Boiler heat exchangers | |

| f) motorbycle and bike | |

| Certificate | ISO9001:2008, TUV, EN10204.3.1 |

| Mechanical Properties(>%) | |||||||

| Grade | Tensile Strength(min) | Yeild Strength(0.2% offset)) | Elongation(%) | ||||

| ksi | MPa | Min | Max | ||||

| Ksi | Mpa | Ksi | Mpa | ||||

| 1 | 35 | 240 | 25 | 170 | 45 | 310 | 24 |

| 2 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| 7 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| 9 | 90 | 620 | 70 | 483 | - | - | 15C |

| 12 | 70 | 483 | 50 | 345 | - | - | 18C |

| Mechanical Properties(>%) | |||||||

| Grade | Tensile Strength(min) | Yeild Strength(0.2% offset)) | Elongation(%) | ||||

| ksi | MPa | Min | Max | ||||

| Ksi | Mpa | Ksi | Mpa | ||||

| 1 | 35 | 240 | 25 | 170 | 45 | 310 | 24 |

| 2 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| 7 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| 9 | 90 | 620 | 70 | 483 | - | - | 15C |

| 12 | 70 | 483 | 50 | 345 | - | - | 18C |

Feature:

1.Low Density and High Strength

2.Excellent Corrosion Resistance

3.Good resistance to effect of heat

4.Excellent Bearing to cryogenic property

5.Nonmagnetic and Non-toxic

6.Good thermal properties

7.Low Modulus of Elasticity

Wir haben weitere Kategorien für Sie. lf Sie die Produkte, die Sie oben möchten, nicht finden können, füllen Sie einfach das Formular aus und sagen Sie uns, welche Produkte Sie aus China importieren möchten.